I attended Advanced Engineering this week, which provided a great insight into present technologies and an understanding of the current state and future prospects of the UK's manufacturing industry. Among the keynote speakers, Stephen Phipson CBE, from Make UK, stood out with his genuine passion for the manufacturing sector. His session on the State of the Nation was not just a series of statistics and challenges but a vibrant and engaging talk that infused humour and wit, making it both informative and enjoyable. Phipson's enthusiasm for the industry showed, and his approach transformed a potentially dry discussion into an engaging talk about the challenges and opportunities facing the manufacturing landscape.

Challenges and priorities

Phipson highlighted the UK manufacturing industry's importance in the national economy by emphasising its significant contribution to the country's exports, accounting for over £200 billion in output. He positioned it as the largest business investment sector in the UK, with a staggering £65 billion invested in business last year.

While the UK government has recently focused on advanced manufacturing as a pillar of economic growth, Phipson expressed concern over the lack of an industrial strategy. He pointed out that the UK is the only industrial country without a defined strategy, which makes it challenging to steer the sector forward coherently and unified.

The discussion covered the multifaceted challenges manufacturers face, including rising energy costs, labour shortages, and the disruptive effects of globalisation and supply chain realignment. Phipson emphasised the critical role of ongoing conversations and advocacy efforts with the government to find solutions and support mechanisms.

However, he is cautiously optimistic about the industry's future. He highlighted the emerging trend of onshoring, where manufacturers are relocating their operations back to the UK because of changes in global supply chains. This trend and the growing decarbonisation-related manufacturing and associated opportunities offer hope for the future.

Phipson strongly advocates for the necessity of an industrial strategy, emphasising its pivotal role in addressing the pressing needs of the manufacturing sector. He reiterated the need for skill development and digitalisation, advocating for a cohesive approach to move the industry forward.

UK manufacturing growth and digitalisation

Stephen presented a positive outlook for the industry's future, citing onshoring and decarbonisation initiatives as primary drivers for growth over the next 5-10 years.

Over the years, there has been a noticeable trend of onshoring, which refers to bringing manufacturing processes back to the UK from overseas. This trend has emerged due to changes in global supply chains and the impact of geopolitical events, which have prompted many of the largest manufacturers to reconsider their sourcing strategies. As a result, there has been an increasing preference among large corporations to source more components and products from within the UK rather than relying solely on international suppliers. This shift in mindset has led to significant investments in the UK's supply chain, indicating a considerable departure from the outsourcing practices of past decades.

According to Phipson, decarbonisation initiatives will significantly affect future manufacturing growth. He highlighted the many opportunities that arise from the push towards sustainability and reducing carbon emissions. These initiatives include the manufacturing of wind turbines, small modular reactors, carbon capture, usage, storage technologies, and the supply chains associated with these ventures. Phipson predicts that these sectors will create hundreds of thousands of new jobs over the next five years, making them a promising avenue for economic and employment growth.

In addition to traditional green energy solutions, the drive towards decarbonisation has also encompassed a variety of innovative technologies and processes. These include developing materials, components, and technologies that promote sustainable practices in the manufacturing industry. These efforts have created numerous opportunities for new businesses and job roles, supporting the broader economic landscape and contributing to the UK's commitment to achieving sustainability goals.

Phipson consistently stressed the importance of developing a comprehensive and cohesive industrial strategy. Such a strategy would act as a guiding blueprint for the sector's growth by aligning various government departments and policies to meet the evolving needs of manufacturing - especially regarding skills development and the integration of digital technologies. This strategic alignment would enable the industry to capitalise on emerging trends, facilitate innovation, and tackle challenges, positioning the UK manufacturing sector as a global leader in the ever-evolving landscape of advanced manufacturing.

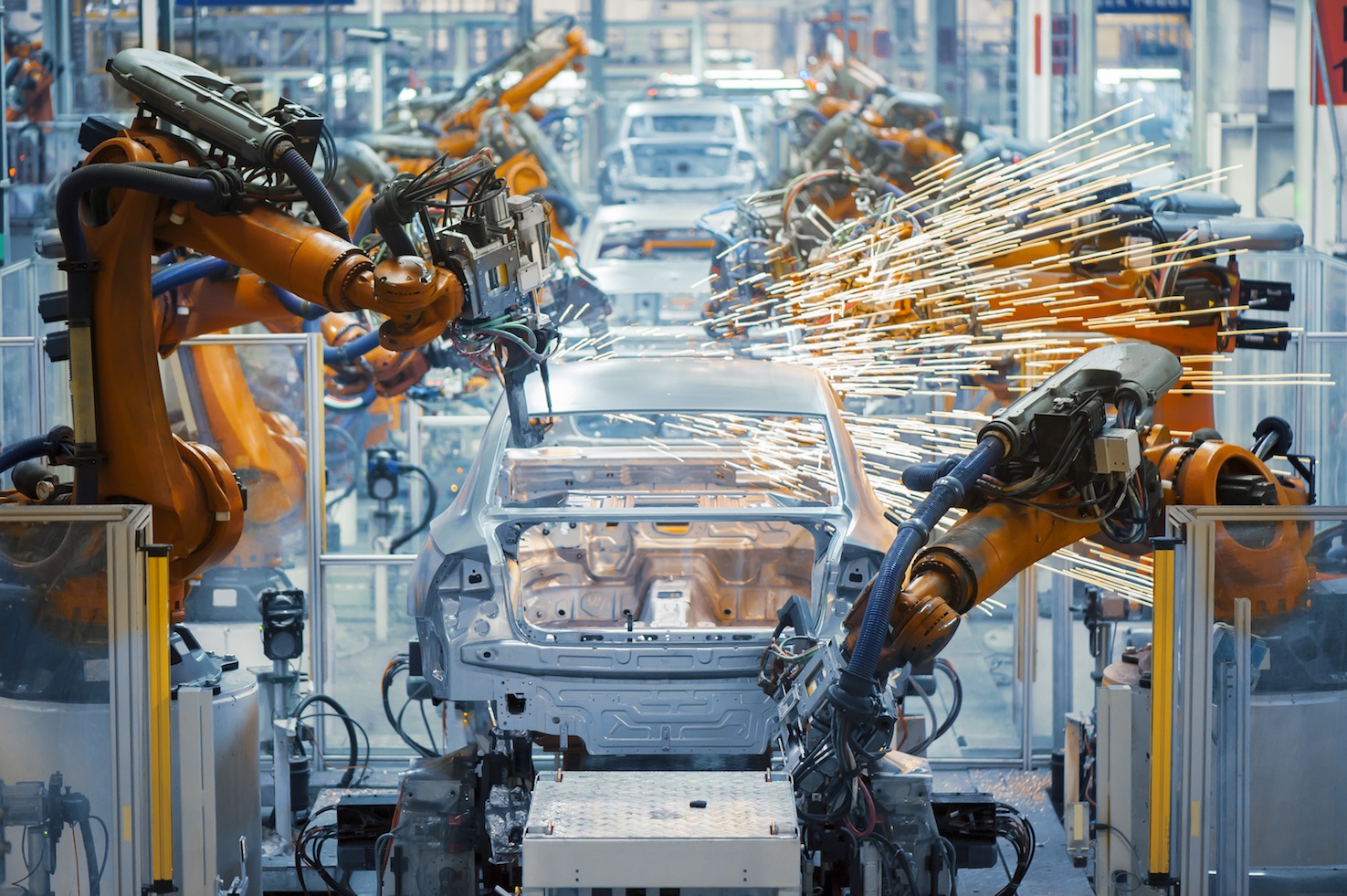

Digitalisation and robotics

According to Phipson, companies that took part in government-backed digitalisation programs experienced remarkable improvements, with productivity surging by 40%. The introduction of digital processes not only optimised manufacturing operations but also led to significant enhancements in energy efficiency. By leveraging data-driven insights, companies were able to adopt more efficient processes, which helped to address the pressing concerns related to high energy costs in the manufacturing sector.

While recognising the progress, Phipson highlighted that the UK still needs to catch up globally regarding robotics integration standards. According to the statistics, the UK has only 107 robots per 10,000 employees, which is lower than the global average of 126. However, he emphasised the positive trend that the country has taken in recent years, as there has been a significant increase in the use of robots in manufacturing processes. This development is seen as a move in the right direction, indicating that the sector is increasingly accepting and implementing automation and robotic solutions.

Skills shortages in UK manufacturing

It’s no secret that the manufacturing sector has a severe shortage of skilled labour. This is particularly evident in crucial vocational areas like toolmaking and welding. These roles are essential for the industry's operations and growth, yet finding individuals with the required skills is increasingly challenging.

Since the introduction of the apprentice levy system in 2016, there has been a decline in apprentice training starters. The system imposes stringent parameters on utilising funds allocated for apprentice training, leading to a significant drop in new apprentices, especially in engineering. This trend exacerbates the problem as further education colleges are also limited in offering engineering apprenticeships.

These challenges highlight the need for a concerted effort to address the shortage of specialised skills within the manufacturing sector. There is a critical need for reforms in training programs, urging a re-evaluation of the apprentice levy system and educational curriculums to align more closely with the demands of the evolving manufacturing landscape. Addressing these skill shortages is essential to fortify the sector's competitiveness and innovation capacity, ensuring sustained growth in a rapidly evolving and technologically advancing global marketplace.

The need for more skilled labour is further compounded by the impending departure of experienced professionals, where approximately 20% of the industry's 2.6 million workforce will retire in the next five years. This statistic underscores the situation's urgency, especially considering the sector's pre-existing shortage of skilled labour.

Infrastructure needs in the UK manufacturing sector

Infrastructure needs formed another crucial aspect of the discussion. Phipson stressed the importance of a robust and modern infrastructure to support the manufacturing sector. He emphasised the necessity for enhanced transportation infrastructure, specifically for increased freight capacity, which is critical for transporting goods, materials, and products across the country. Phipson lamented the cancellation of the northern leg of the HS2 rail project, which was seen as detrimental to freight capacity, an essential factor for the manufacturing industry's growth and competitiveness.

The importance of digital infrastructure, especially 5G networks, was emphasised in areas where manufacturing activities are concentrated. The successful integration of advanced manufacturing processes depends on a robust and accessible digital infrastructure, which makes the urgent need for digital infrastructure clear.

Advocating for government support

Energy market reform also emerged as a crucial aspect to bolster the UK's competitiveness within the manufacturing industry. Phipson stressed the urgent need for significant regulatory changes, as UK industrialists paid 63% more for energy than their European competitors - a staggering disparity.

The conversation shifted towards enhancing productivity and energy efficiency through digital technologies. Phipson advocated for increased government support and the national rollout of programs similar to government-backed initiatives that have demonstrated substantial increases in productivity by leveraging digital processes. These initiatives have proven immensely beneficial, significantly improving manufacturing operations and energy efficiency.

The discussion also included concerns regarding business rates and research and development (R&D) tax credits. Phipson highlighted the need for business rates reform, emphasising that forthcoming changes in business rates, particularly the considerable increase projected for manufacturers (27% as opposed to the average of 7% across all businesses), could prove detrimental to the sector's growth and sustainability. Additionally, the withdrawal of R&D tax credits had impeded smaller manufacturers' innovation and development efforts. Government support in these areas was regarded as pivotal to fostering innovation and competitiveness within the manufacturing industry.

Another critical issue highlighted was the dissatisfaction with the government's export strategy. Phipson voiced disappointment, noting that the existing export strategy primarily focused on service technologies and failed to support the manufacturing sector adequately. He stressed the need for the government to focus on exporting products and aligning strategies with the manufacturing industry's needs.

Overall, the conversation emphasised the necessity of government intervention and support to address the multifaceted challenges faced by the manufacturing industry and foster innovation and competitiveness within the manufacturing industry.

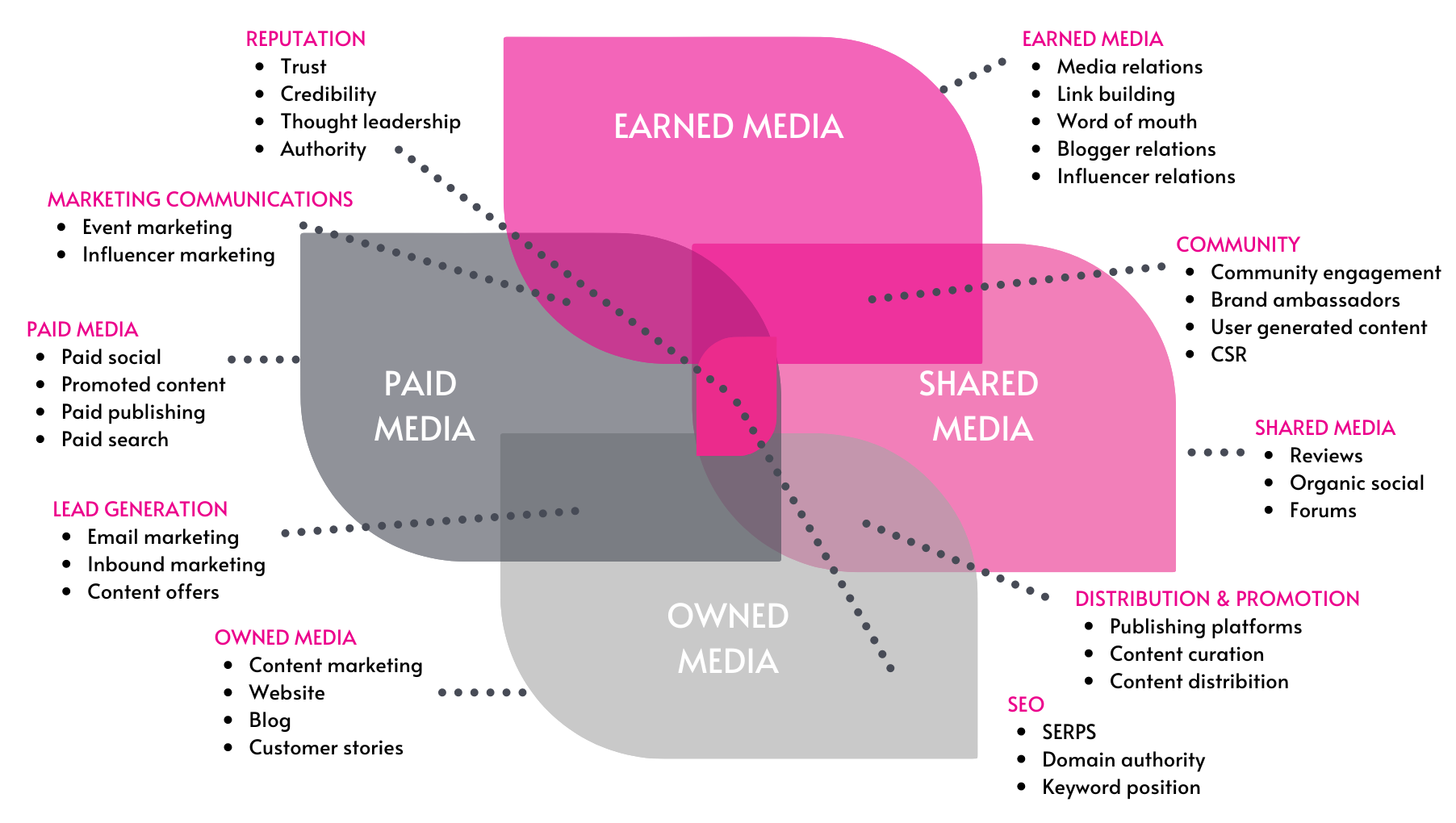

Marketing’s role for UK manufacturers

It seems fitting that we share our insights as a marketing agency for manufacturing companies. Marketing is often considered less significant in manufacturing than production, innovation and operational efficiencies. However, it is a vital component that directly influences the success and sustainability of manufacturing businesses. It connects the creation of goods to their end-users by communicating product value, benefits, and innovation to prospective customers.

Effective marketing strategies in the manufacturing industry are crucial for fostering brand awareness, building customer trust, and differentiating products from competitors in a highly competitive market. It plays a central role in guiding manufacturers to present their offerings, targeting the right audience, and adapting to evolving market needs. Additionally, in an era of increasing focus on sustainability and ethical manufacturing practices, marketing is essential in showcasing a company's commitment to responsible and eco-friendly manufacturing, appealing to socially conscious customers and partners. Ultimately, a well-crafted marketing strategy is indispensable in shaping a manufacturing company's reputation, its market positioning, and its ability to remain competitive in an ever-evolving landscape.

Conclusion

Stephen Phipson's State of the Nation session provided an insight into the complex landscape of the UK's manufacturing industry. Phipson highlighted the challenges and successes within the sector and emphasised the need for a comprehensive industrial strategy. He passionately advocated for the manufacturing sector, not only to address immediate obstacles but also to look forward to a future full of opportunities. The discussion emphasised the importance of digitalisation, decarbonisation, addressing skills shortages, and finding solutions for labour challenges.

The manufacturing industry is facing many disruptive forces and global changes. There is a need for a unified approach from the government, with aligned priorities and departments to support and strengthen the industry. The success of the manufacturing sector depends on its ability to evolve and innovate, and to adapt to the changing global marketplace. The future of UK manufacturing looks promising if there is collaboration, strategic planning, and a shared vision. The industry must be resilient and innovative, and move in a unified direction to succeed.

Share this

You May Also Like

These Related Stories

What the new Manufacturing Council means for UK businesses

What topics to cover in industrial content marketing